- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views:150 Author:Site Editor Publish Time: 2016-11-15 Origin:Site

How The Individual Components Were Made:

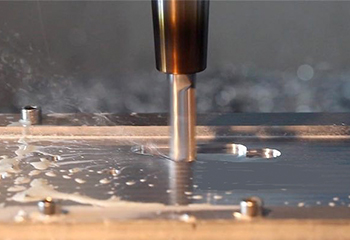

Step 1. CNC Machining

We chose 6061-T6 aluminum for the main parts. This is a commonly available aluminum alloy that machines well, is not too expensive and looks great after anodizing.

Also, aluminum is lightweight, making the Snuffmaster easy to carry in a pocket or bag. A 3-axis CNC mill is used

to route the profile of the case.

Step 2. Sandblasting

After milling there were some fine machine marks and scratches on the metal. To remove these, all of the parts needed

to be placed in a sandblasting chamber and carefully sanded with a fine grit. This gives the parts a uniform matte finishand

removes any burrs.

Step 3. Anodizing

Sandblasting provided the ideal surface texture for accepting the anodizing process. After a thorough cleaning, parts were

placed on trees to keep them separate and then dunked into a chemical tank. This is a passivation technique that adds color

while increasing corrosion and scratch resistance. And of course it looks great too.